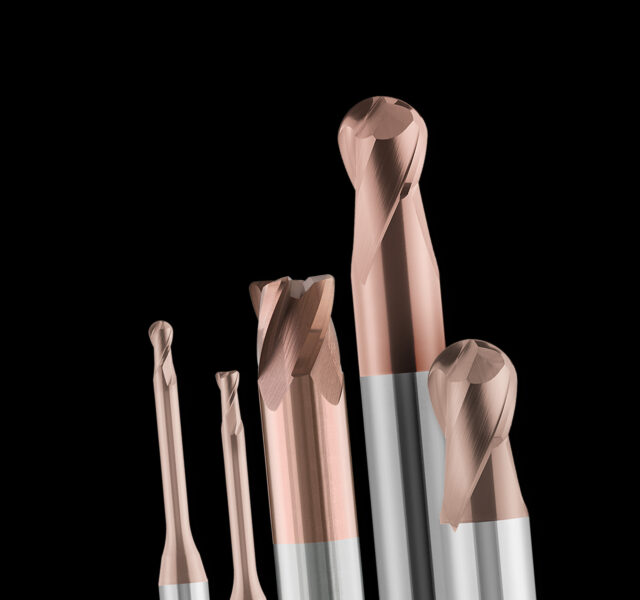

Mold end mills

0043

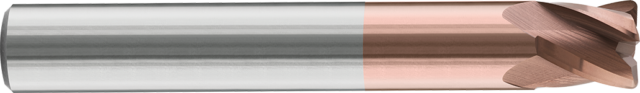

4 flute end mill 3xD for trochoidal milling of hardened steel

0044

4 flute end mill 4xD for trochoidal milling of hardened steel

007w

4 flute high feed end mill for roughing and copy milling at high feed

008w

4 flute high feed end mill for roughing and copy milling at high feed of hardened steel

1144

4 Flutes end mill unequal flute spacing for roughing

1144S

4 Flutes corner radius end mill unequal flute spacing for roughing with neck relief

1144A

4 Flutes corner radius end mill unequal flute spacing for roughing with tapered neck relief

1142

4 flute end mill for semi-finishing and finishing

1141

3 flute end mill for semi-finishing and finishing

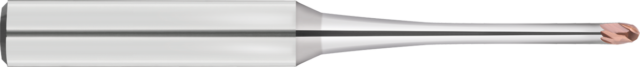

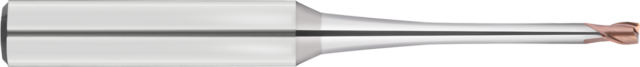

7725

2 flute ball nose end mill,regular version

7725S

2 flute ball nose end mill regular version with neck relief

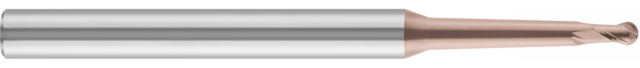

7726

2 flute ball nose end mill, long version

7726S

2 flute ball nose end mill, long version with neck relief

7727

2 flute ball nose end mill, regular version of hardened steels

7727S

2 flute ball nose end mill, regular version with neck relief of hardened steels

7729

2 flute ball nose end mill, long version of hardened steels

7729S

2 flute ball nose end mill, long version with neck relief of hardened steels

1149

3 flute ball nose end mill long version

1149S

3 flute ball nose end mill long version with neck relief

1149A

3 Flutes ball nose end mill with tapered neck and reinforced shank

1147

4 flute ball nose end mill long version

07210

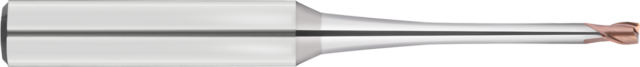

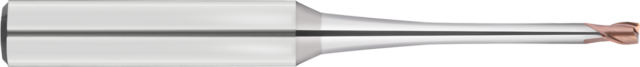

2 flute corner radius end mill for ribbing

06210

2 flute corner radius end mill for ribbing with reinforced shank

05210

2 flute corner radius end mill for deep milling with tapered neck and reinforced shank

04210

2 flute corner radius end mill for deep milling with tapered neck and reinforced shank

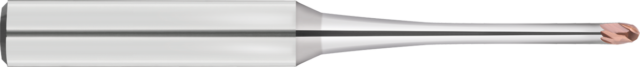

07220

2 flute ball nose end mill for ribbing

06220

2 flute ball nose end mill for ribbing with reinforced shank

05220

2 flute ball nose end mill for ribbing with tapered neck and reinforced shank

04220

2 flute ball nose end mill for ribbing with tapered neck and reinforced shank

1155

Multi-flute end mill for finishing

1143

6 flute end mill regular version for finishing of hardened steels

1145

6 flute end mill long version for finishing of hardened steels

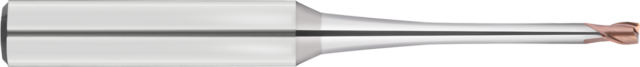

1340

2 flute ball nose end mill with tapered neck for engravings

1350

2 Flute end mill for gasket seat

2 flute ball nose end mill for ribbing with tapered neck and reinforced shank

2 flute corner radius end mill for ribbing

2 flute ball nose end mill for ribbing with tapered neck and reinforced shank

2 flute corner radius end mill for ribbing with reinforced shank

2 flute corner radius end mill for deep milling with tapered neck and reinforced shank

4 flute end mill for semi-finishing and finishing

2 flute corner radius end mill for deep milling with tapered neck and reinforced shank

2 flute corner radius end mill for deep milling with tapered neck and reinforced shank

2 flute ball nose end mill for ribbing with tapered neck and reinforced shank

2 flute ball nose end mill, long version with neck relief of hardened steels

2 flute corner radius end mill for deep milling with tapered neck and reinforced shank

2 flute corner radius end mill for deep milling with tapered neck and reinforced shank

More than 10.000 new items

with wide availability in stock

State-of-the-art geometries and coatings for the sector of moulds and dies

The renewed SILMAX Catalogue for moulds and dies features over 10,000 new items, which enable to perform complex machining operations on the most difficult-to-cut materials, with hardness up to 65 HRC.

The significant extension of the range concerns the number of tools introduced, the geometries with tighter manufacturing tolerances, the latest Balzers coatings, combined with post surface treatments for top performance.

With the new SILMAX mould line, there are numerous customisation possibilities so that the most suitable and high-performance solution can be found in real time thanks to the large stock availability.

Customisation

In a sector where specialisation and customisation of products are increasingly demanded, Silmax offers a line of products to be customised according to one’s needs, with a varied selection of radiuses and neck reliefs, available for immediate delivery or on request.

Tolerances

Tighter manufacturing tolerances thanks to a continuous research & development activity carried out at our in-house production facilities and thanks to the use of state-of-the-art CNC machines.

Coatings

State-of-the-art TiSiN-based Balinit® Tisaflex coating produced with Ingenia and Innoventa Kila units at our Italian factories. Tisaflex represents the best solution to machine difficult-to-cut materials, high-strength steels, chrome steels and hardened materials above 60HRC.

3 and 4xD end mills for dynamic milling

New line of 3 and 4xD end mills for dynamic milling, with dedicated geometry for materials with hardness up to 65 HRC.

Thanks to the special geometry of these end mills, it is possible to obtain milling results with higher precision and higher quality compared to traditional solutions, significantly reducing processing times and increasing productivity.

Engraving, micro end mills for engraving

Engraving is a complete line of micro engraving end mills. These tools are specially designed to obtain perfect and precise engravings on a wide range of materials, including the most difficult ones to machine.

End mills for O-Ring grooves

End mills for O-Ring grooves are a novelty designed to produce suitable grooves for O-Rings, making the production of components more precise and reliable, thanks to their ability to machine quickly and uniformly.

SILMAX 360°

Consulting service

Silmax 360° represents a consulting service to help users choose the most appropriate machining strategies and the best-performing Silmax tools, with the new end-mill programme for machining “HRC” dies and moulds, in cooperation with TopSolid.

Silmax intends to be a partner of reference for enterprises that manufacture dies and moulds for all sectors. The technical experts of Silmax are able to assist customers in all machining stages from feasibility studies to CAD-CAM programming, to support them with innovative solutions, in reducing production costs and improving the quality standards of their finished products.

Specialist technical support in the selection of the appropriate strategy for the machining and manufacturing of dies and molds.

Study and optimisation of tool paths. Design of the best performing tool. Use of the most advanced CAD/CAM systems.

Creation of a database regarding direct experiences with end users, at the disposal of all customers for information on the various types of machining, with new strategies and optimizations.

Study and creation of ISO programmes for use on the main machine tools, for specific applications according to the required, different types of machining.

Analysis, testing and optimisation of current strategies and proposal of the best performing tool with the most adequate CAM path.